Simplify Design Modification by Accurate Thermal Simulation of Baking Oven

We are excited to announce our ground-breaking research, now published on the SAE International platform, which presents an innovative approach to thermal simulations in automotive paint shops.

Why it matters

Paint shops are vital for achieving high-quality vehicle finishes but are also among the most energy-intensive aspects of car manufacturing. With the shift towards electric vehicles necessitating lighter and more complex body designs, our new simulation process enables precise curing without the time and resource drain of traditional prototyping.

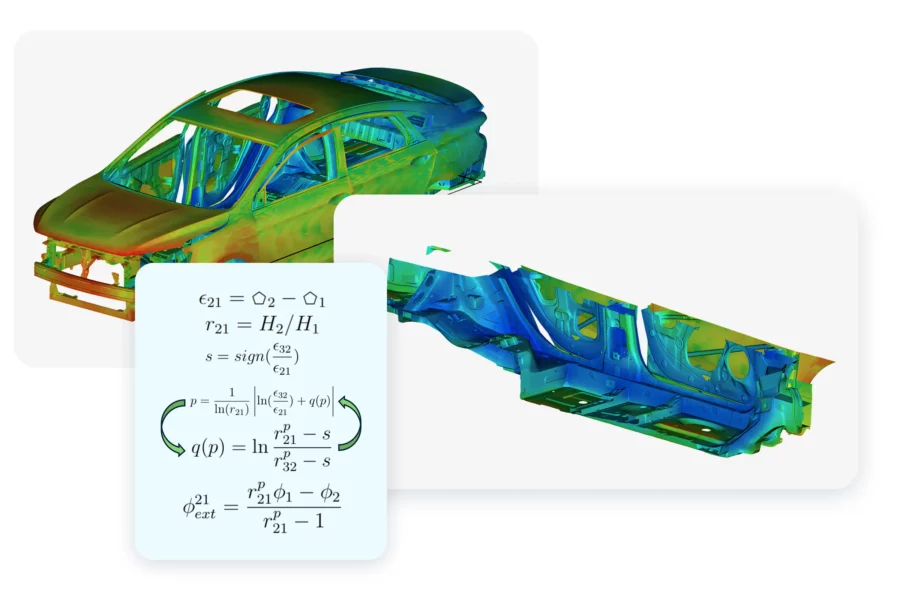

Utilizing the Lattice Boltzmann Method (LBM), our study titled, “Simplify Design Modification by Accurate Thermal Simulation of Baking Oven,” allows for rapid, high-fidelity simulations of paint curing processes. No longer do you need to wait for complex preprocessing or mesh generation. This means that we can simulate massive computational domains quickly and accurately, considering real-time oven conditions and specific changes in parts of the BIW design. This technique significantly reduces the need for physical prototypes, thus lowering costs and resource usage, and it aligns with sustainable development goals for more efficient energy use in industrial processes.

Key Benefits

- Reduced Costs and Resources: Minimize the number of prototypes, saving on materials and speeding up car body development.

- Enhanced Paint Quality: Achieve consistent, high-quality finishes that meet strict corrosion protection standards.

- Greater Efficiency: Adapt quickly to new designs, keeping pace with the fast-evolving automotive sector.

Our innovative simulation technology not only boosts efficiency but also enhances the quality of outputs in automotive paint shops, proving essential in a competitive industry.

Discover the full potential of our findings by accessing the complete paper here.