Multiphysics Modeling of Industrial Top Coating with Rotary Bells

We’re thrilled to introduce transformative advancements in paint shop technology detailed in our latest publication, “Multiphysics Modeling of Industrial Top Coating with Rotary Bells” available on the SAE International platform. This study showcases a significant leap forward in the precision and efficiency of automotive coating applications using Rotary Bell Atomizers (RBA).

Revolutionizing Paint Application

RBAs are favoured in the industry for their ability to uniformly coat complex car geometries swiftly. However, achieving high transfer efficiency—where up to 95% of the paint adheres to the vehicle design—has been a challenge, dependent on numerous variable factors. Our latest research utilizes a sophisticated multidisciplinary framework to simulate the paint coating process with unprecedented accuracy, allowing for a significant reduction in both prototype trials and production costs.

Our Innovation

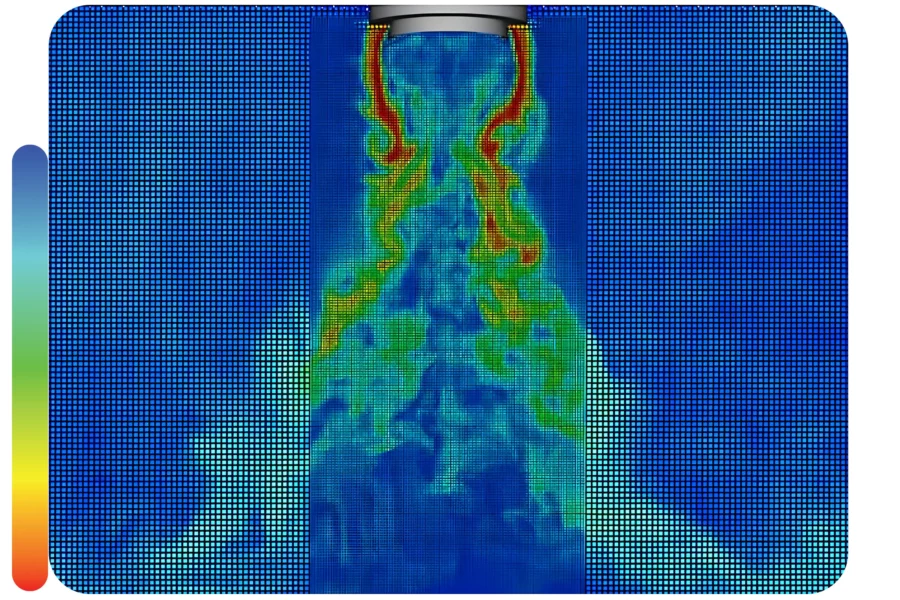

Our approach allowed us to develop a coupled multi-physics solver which employs several advanced methods: Lattice Boltzmann Method (LBM) for air flow simulation, ensuring detailed airflow dynamics around the atomizer. Lagrangian Particle Method for tracking paint droplets, offering insights into their precise paint flow behaviour during application process. Thin Film Solver for accurate thickness calculation, ensuring consistent quality of coating across different car parts.

By simulating the entire process virtually, we effectively reduce material waste and diminish the emission of harmful volatile organic compounds (VOCs), addressing both economic and environmental concerns.

How is this beneficial?

- Increased Transfer Efficiency: Optimize paint usage, minimizing overspray and reducing operational costs.

- Faster Development Cycles: Accelerate the time-to-market for new vehicle designs with reliable cost predictability.

- Reduced Environmental Impact: Lower the output of non-deposited paint particles, significantly cutting down on the industry’s ecological footprint.

Our breakthrough in multiphysics modelling not only streamlines the painting process but also enhances the uniformity and quality of automotive coatings at high reliability. This innovation is set to redefine standards in automotive paint shops, making advanced simulation an integral part of the painting process. Explore the depth of our research and its implications for your operations by accessing the full paper.