E-Coating and its complex process

The automotive industry has been dealing with an unresolved problem: how can energy consumption be opti-mized while also providing optimal corrosion protection of the car body? Electrophoretic deposition (EPD) entails immersing the car body in a tank of paint diluted with water, through which an electrical current is passed. Applying the voltage triggers an electrolysis process that creates a highly resistant bond between the paint and the charged body.

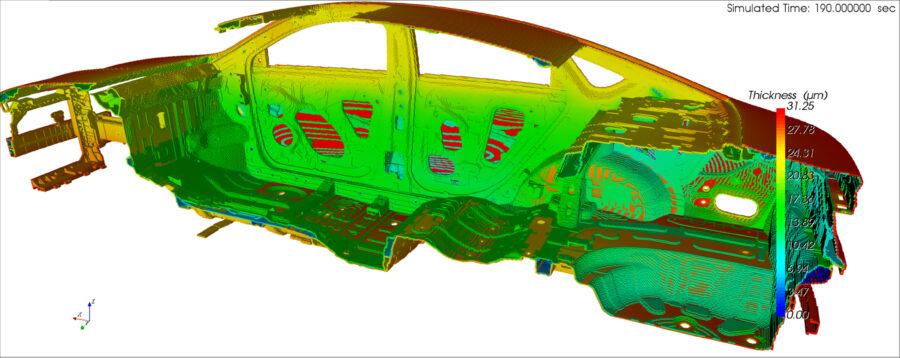

The EPD process allows the user to manipulate the voltage in small doses. This leads to overcoating of some areas of the cars and undercoating in others. In most cases, the imposed voltage is simply too high and not well dis-tributed.

This is because the car body geometries are too complex to define optimal voltage programs manually. Until now, the problem has been left pending.

ESS has the answer: A software solution that enables paint shop experts and designers to optimize these parameters upfront.

alsim Paint Shop E-Coating

ESS is passionate about finding answers that allow for highly accurate simulations of the E-Coating process and has come up with a unique software solution. The software considers comprehensive testing and validation processes within defined parameters.

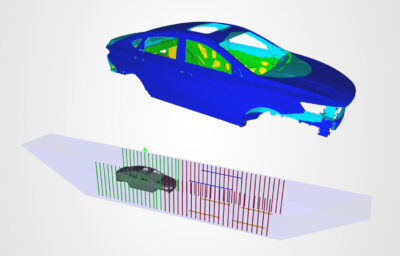

How does the ESS solution work? First, paint characteristics of the different substrates used are derived. Thereafter vehicle characteristics are considered using exact CAD of BIW and the connection be-tween parts while maintaining holes are prepared.

Thirdly, the process parameters such as voltage program, tem-perature, fluid flow and line speed are taken into consideration. Our e-coating simulation is unlike any other because it can also determine the distribution of the paint particles in the bath and can find weak spots that may have been incorrectly introduced through fluid flow.

The effect of fluid flow is always considered by our software because fluid flow, the distributed and electric charged paint particles have a major impact on final thickness cov-erage. Due to this, the diffusion of paint particles on the BIW is, of course, also considered.

All of this is possible with our E-Coating software solution which in turn creates superior results during the BIW design process. alsim Paint Shop E-Coating optimizes conflicting targets and minimizes energy consumption by avoiding under and over-coating.