Our clients’ triumphs are the heartbeat of ESS’s mission. Our long-standing collaboration with the premium car manufacturer Audi has been one such success – that helped us define our paint shop simulation solutions and attain product superiority in the market.

8 years of excellence

Our proud relationship with Audi, that started 8 years ago, since 2016, has helped them to optimize their designs and has led to several improvements in their paint shop processes. The simulation results from each of our modules, provide precise visualization of a specific process in automotive paint shop. Gido Hoppe, who is responsible for our tools at Audi, praised our software for its accuracy in generating results without much effort. He said, “ESS’s alsim Paint Shop helps us determine the actual process at a very early stage with uncanny realism – and has been the most useful in fixing the problem areas we encounter.”

“The usability and the high-level of automation that’s available with ESS solutions, makes optimization of our processes, almost effortless!”

As per Gido, “The usability and the high-level of automation that’s available with ESS solutions, makes optimization of their processes, almost effortless!” With the proactive support provided by the ESS’ experts, it is not challenging to train non-technical users on alsim Paint Shop suite.

alsim Paint Shop modules

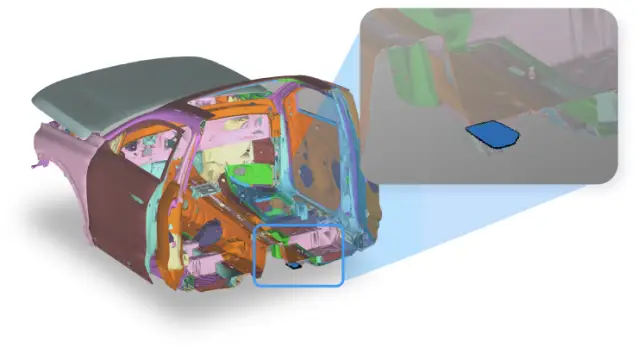

The alsim Paint Shop Dip Paint module, one of the initial modules used by Audi, showcased its capability by enabling Audi to identify and mitigate potential issues during the dipping and drainage phase. Once the results from the module were validated by Audi, and further calibration were done, our team worked closely with Audi to get the best out of the results generated from alsim Paint Shop. The Dip Paint module, now being used to determine the problem areas with dip-in and dip-out process, is not just about problem-solving – but rather about reimagining efficiency.

Audi uses alsim Data Cleaning Merge for preparation of the geometry before simulation. As of now, in addition to Dip Paint, Audi has also been using other modules in the alsim Paint Shop suite to determine the problems areas for other processes in their paint shop. This includes modules like E-coating for the electrophoretic deposition process and Flood Waxing for the cavity preservation in BIW. In addition, the intricate challenges presented by EV components, like the aluminium profiles in rocker panels, are adeptly managed through our modules especially the Dip Paint and Ecoating modules.

The impact

Reducing prototypes for sustainability is an indispensable topic, and yet a challenging one at that. Audi being a pioneer at pushing boundaries of technology and design, is striving to minimize the number of prototypes used in their paint shop during a vehicle development. Simulation results greatly assist in predicting faults at an early stage and avoiding late change corrections. This strategy allows for precise adjustments and efficiency improvements, minimizing the reliance on physical prototypes, saving time, and cutting costs.

“Audi’s approach of reducing prototypes has been strengthened through the integration of alsim Paint Shop modules in our paint shop.”

Our journey with Audi is a testament to the power of partnership and innovation. With a reservoir of potential waiting to be tapped, we are eager to explore the future with Audi, and to continue shape the automotive landscape.