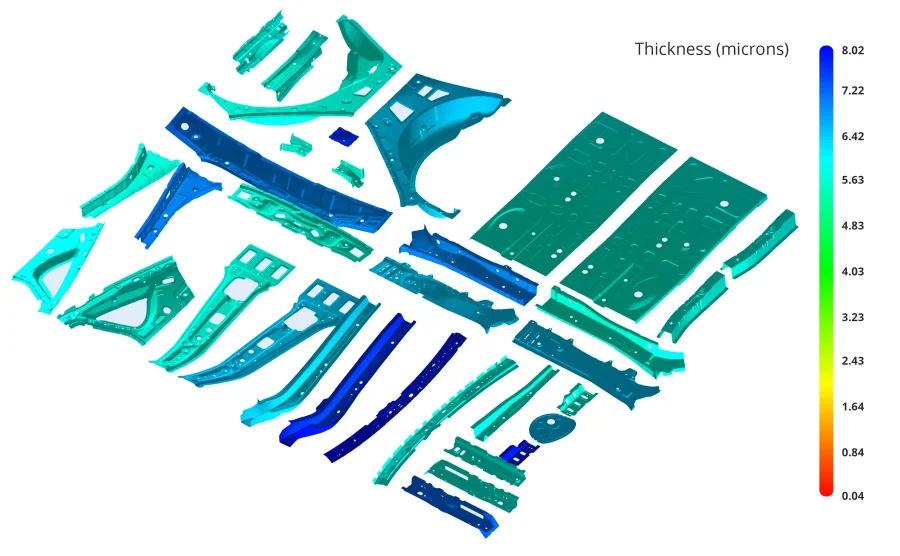

Designed for all types of alloys

Different aluminum alloys influences the oxide layer formation.

We consider these influences, providing accurate simulations for parts with different alloys.

Current and Voltage Control

We support – current-controlled & voltage-controlled processes.

Accurately analyze the final thickness of the oxide layer for each – constant cathode voltage and constant current density.

Reliable scientific approach

Based on Faraday’s law of electrolysis, and a Partial differential equation model to accurately simulate the process.

Advanced numerical PDE solver – to solve problems with large scales – accurately calculating thickness increase in each time step.

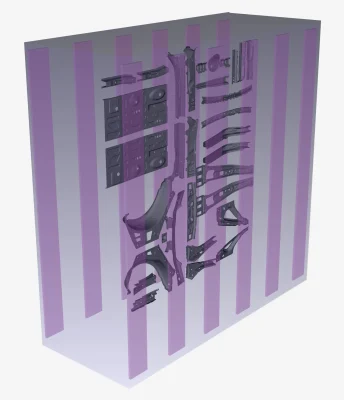

Efficient Pre-Processor and GUI

alsim Data Cleaning Merge – powerful pre-processor for 30+ CAD file formats.

Easily transform design files into 2D surface mesh data for simulation.

Results can be easily post-processed using the intuitive Graphic User Interface (GUI).

Parameter Analysis

Various parameters considered – electro-chemical equivalent, conductivity/resistivity of the oxide layer and electrolyte etc.

Determined from – lab experiments, and calibrated through industrial measurements, for highly precise simulations.

Titanium/Aluminum Jigs

Titanium jigs can be reused for a long time, while aluminum jigs are consumable.

Accurately simulate final thickness for both types of jigs – titanium or aluminum.

Great tool for Design Improvement

Improve low thickness from cavities – find best hole configurations using rapid analysis.

Easily Identify optimal locations and contacting points for jigs.